Who wouldn’t agree that precise temperature control is critical, especially when it comes to heating elements in an oven? Maintaining the right temperature plays a crucial role in ensuring efficient energy consumption and achieving desired results, be it in cooking or industrial processes. To handle this, we turn to technology, and the Proportional-Integral-Derivative (PID) controller is a solution that comes to the forefront.

The PID controller, as the name suggests, uses a method of control loop feedback. It helps regulate the temperature in heating elements, among other things, by calculating the deviation between a set point and a process variable. This controller provides more accurate and stable temperature control, making it a popular choice for oven controllers.

Think about the last time you baked a cake. Getting the temperature right can make all the difference between a delightful, moist cake and a dry, overbaked disappointment. A PID oven controller takes away the guesswork and gives you an expert grip on temperature control. It is a tool that offers precision, stability, and energy efficiency.

Fundamental Aspects of PID Oven Controller

What is a PID Controller?

A PID controller is an intricate piece of technology that excels in situations demanding high precision, like controlling the temperature of an oven. The “PID” stands for Proportional, Integral, and Derivative, which are the three distinct types of feedback control used in this controller.

Proportional Control in PID

The Proportional control in a PID controller minimizes the Rate of Error. It’s essentially a corrective action that’s directly proportional to the current error value.

Importance of Integral Control

Integral control detects and corrects trends in error over time, reducing the steady-state error. It’s like a vigilant watchman, always looking out for persistent, minor discrepancies that could impact the system’s performance.

The Role of Derivative Control

The Derivative control responds to the rate of change of the error, thereby providing a way to anticipate future system behavior. It’s like a skilled fortune teller, predicting and preempting future errors to maintain system stability.

Advantages of PID Control for Heating Elements

Precision Temperature Control

In my experience, the most significant advantage of using a PID controller for heating elements is the precision it offers. The controller minimizes temperature fluctuations, ensuring a consistent temperature throughout the process.

Stability and Consistency in Heating

Stability is another huge selling point for PID controllers. They provide consistency in heating, a trait that’s invaluable in cooking and industrial applications.

Energy Efficiency and Cost Savings

PID controllers also contribute to energy efficiency by maintaining optimal temperature, resulting in lower energy consumption. And who wouldn’t appreciate cost savings on their energy bill?

Setting Up a PID Oven Controller

Equipment and Components Needed

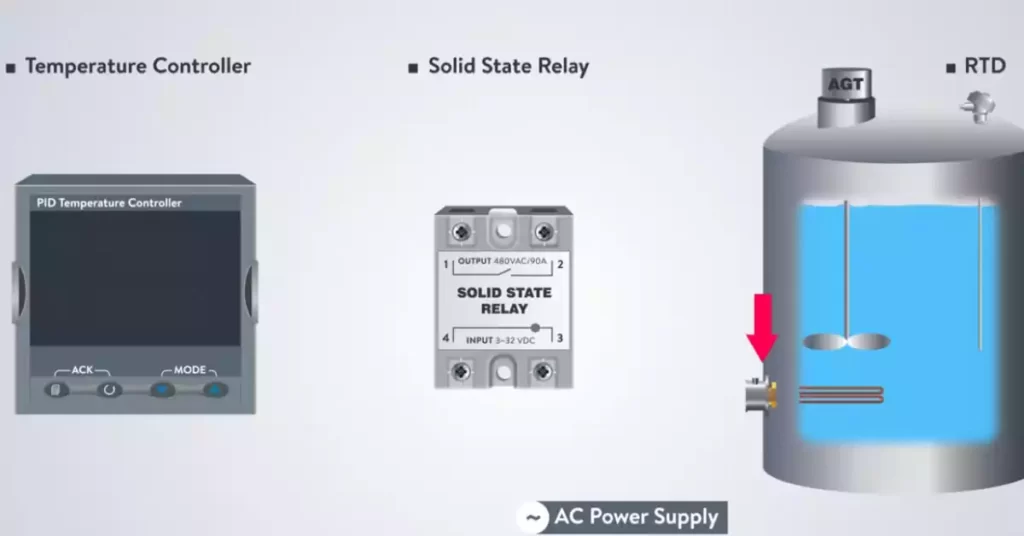

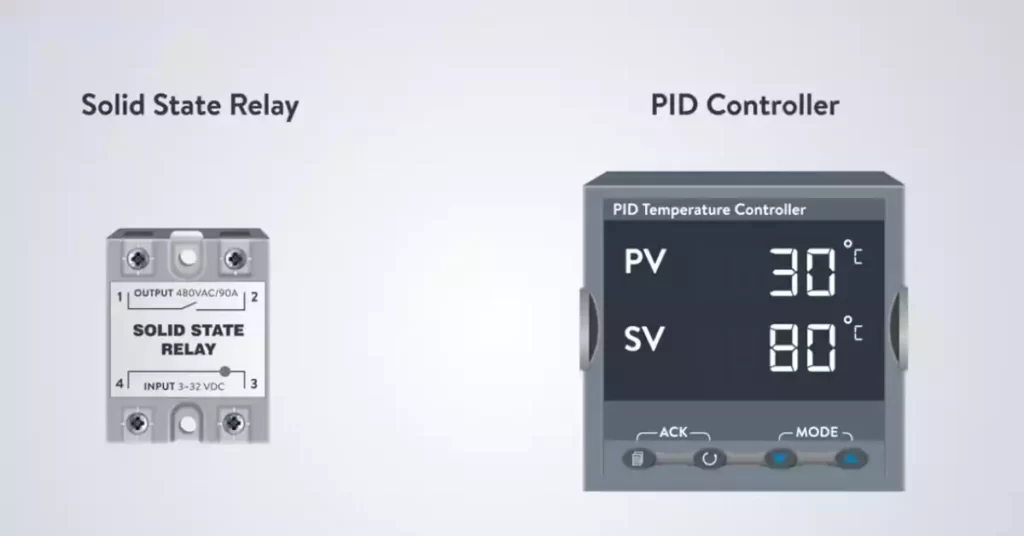

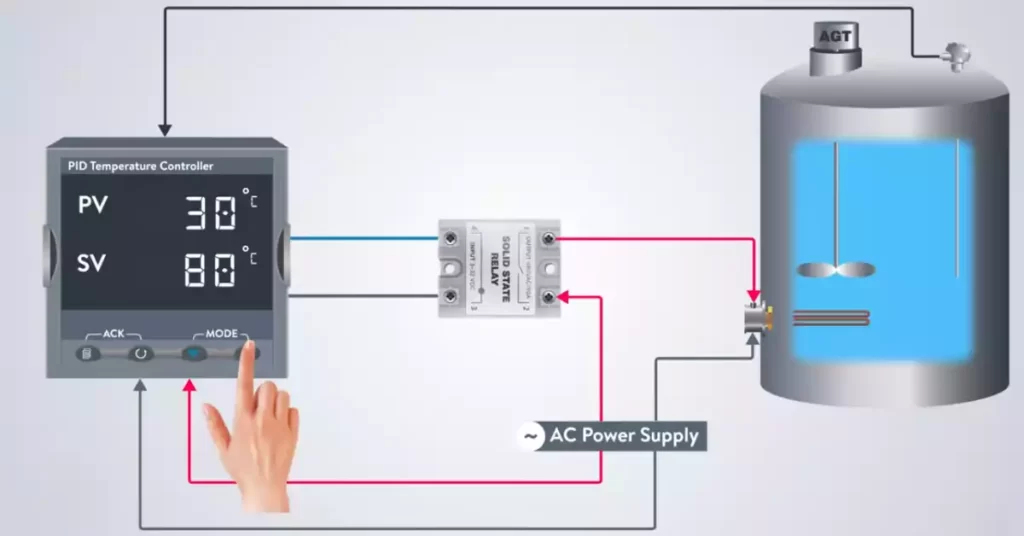

To set up a PID Oven Controller, you’ll need some basic equipment. This includes a PID controller, a temperature sensor, a Solid-State Relay (SSR), and an oven with a heating element.

Step-by-Step Process for Setup

Setting up a PID controller may seem a daunting task at first glance, particularly if you’re not well-versed in technical procedures. However, fear not. I have simplified the process into an easily digestible, step-by-step guide.

Choose the Right PID Controller: The first step is to choose a PID controller that suits your needs. Different controllers come with varying features and specifications, so be sure to choose one that matches your oven’s requirements.

Install the Temperature Sensor: Next, you will install the temperature sensor in your oven. This sensor is critical because it allows the PID controller to monitor the current temperature inside the oven.

Connect the PID Controller to the Heating Element: The PID controller must be connected to the heating element to control the temperature. This typically involves connecting the controller to a Solid-State Relay (SSR), which in turn is connected to the heating element.

Configure the PID Controller: The next step involves configuring the PID controller. This includes setting the desired temperature (setpoint) and tuning the PID parameters. The parameters will differ based on your specific oven and needs, but they generally involve adjusting the Proportional, Integral, and Derivative values.

Test the Setup: Finally, it’s time to test your setup. Turn on the oven and observe the heating process. If the PID controller is correctly set up and tuned, the temperature should reach and maintain your set point.

Calibration of a PID Oven Controller

What Does Calibration Mean?

When we talk about calibration in the context of a PID Oven Controller, we refer to the process of fine-tuning the controller to ensure optimal performance. It’s like fine-tuning a musical instrument to ensure it plays the right notes.

Importance of Calibration for PID Controllers

Calibration of PID controllers isn’t just a desirable step; it’s a necessity. Why? Because every oven is unique. The way your oven retains heat, how fast it heats up, and many other factors are specific to your oven. Calibration helps the PID controller learn these specific characteristics, ultimately ensuring better temperature control.

Calibration Process Overview

Calibrating a PID controller involves several steps. It typically includes an initial test run of the oven, observing how the temperature behaves, and then adjusting the PID parameters accordingly. The idea is to reach a point where the oven’s temperature control is as accurate as possible, with minimal fluctuations.

Troubleshooting Common PID Controller Issues

Overheating Problems

Overheating is a common issue that can arise when using PID controllers. If you’re finding that your oven is regularly overheating, it could be due to a few factors. Perhaps the PID parameters are not correctly set, or there may be a problem with the heating element or the sensor.

Inconsistent Temperature Control

Another common problem you might encounter is inconsistent temperature control. If the oven’s temperature fluctuates wildly, it might be an indication that the PID controller is not appropriately tuned. The Integral and Derivative parameters play a crucial role here, and fine-tuning them can help stabilize the temperature.

Tips to Rectify Common Issues

Resolving issues with PID controllers often involves a bit of trial and error. However, a systematic approach can help. Start by confirming that all hardware components are correctly installed and working. If the hardware is fine, the issue likely lies with the PID parameters. Consider retuning the controller or seeking help from a professional.

Frequently Asked Questions

Can I use a PID controller for other applications apart from oven temperature control?

Yes, PID controllers are versatile and can be used in numerous applications requiring precision control, including motor speed control, fluid level control, pressure regulation, and more.

Are there alternatives to PID controllers for oven temperature control?

While PID controllers are commonly used for oven temperature control due to their precision, alternatives do exist. These include ON/OFF controllers and Bang-Bang controllers. However, these alternatives may not offer the same level of precision as PID controllers.

How often should I calibrate my PID Oven Controller?

The frequency of calibration largely depends on your usage and the specific characteristics of your oven. However, as a general rule, recalibrating your PID controller whenever you notice significant temperature discrepancies or after any significant maintenance on your oven is a good practice.

Conclusion

Precise control of oven temperature is a necessity, and a PID controller provides this with a level of sophistication and accuracy that is hard to match. From understanding the fundamental aspects of PID controllers to setting one up and troubleshooting common issues, we’ve journeyed through the intricacies of this fantastic technology.

The precision, stability, and energy efficiency afforded by PID controllers make them a go-to choice for many applications. With a good understanding and proper handling, you can make the most of these devices, enhancing your oven’s performance and ultimately achieving better outcomes, be it in cooking or industrial settings.

We’ve also clarified some of the most frequently asked questions about PID controllers. Armed with this knowledge, you’re now better prepared to make informed decisions about implementing and using PID controllers in your oven. With the right PID controller setup, precise temperature control is not just a possibility; it’s a certainty.