In the realm of knife-making, induction forging has emerged as a revolutionary technology. It’s a modern method that offers unparalleled control, efficiency, and safety when compared to traditional heating techniques. The craftsmanship of knife-making is brought to new heights with induction forging, a technology rooted deeply in science.

Induction forging relies on the power of electromagnetic fields to generate intense heat without any physical contact. This method is highly effective in heating metals such as the ones used in knife-making. Its application in this field marks a significant advancement, allowing for better precision, energy efficiency, and safety.

Induction heating is reshaping the landscape of knife-making. This process, where a metal is heated by subjecting it to a high-frequency electromagnetic field, offers numerous advantages that traditional heating methods simply cannot compete with.

The Science Behind Induction Forging

Basic Principles of Induction Heating

Induction heating is founded on two fundamental principles: electromagnetic induction and the Joule effect. When an alternating current is passed through an induction coil, it generates an alternating magnetic field. This field induces a flow of electrons in the metal piece, causing it to heat up due to the Joule effect.

Induction Forging Process for Knife Making

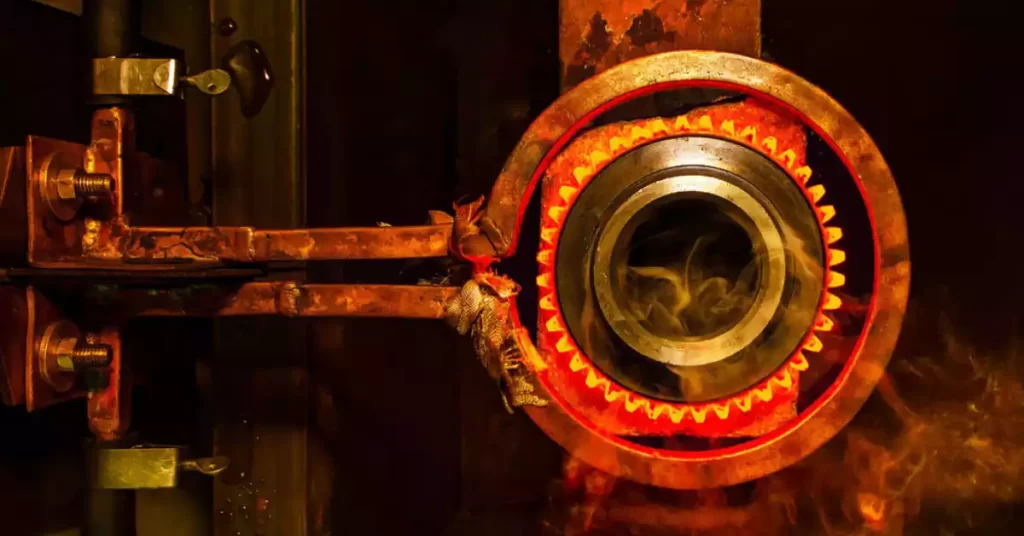

When it comes to knife-making, the metal bar is placed in the induction coil. As the current oscillates, the induced magnetic field excites the electrons in the metal, generating intense heat. This heat is utilized to soften the metal, readying it for the forging process.

Interested in a budget-friendly high-frequency induction heater? Check out the U.S. Solid 15KW 30-80 KHz Induction Heater or the CHMING 15KW 30-100KHz Induction Heater (View on Amazon). Both are great options as induction forge.

The Advantages of Induction Forge in Knife Making

Precision and Control in Heating

One of the prime advantages I’ve observed in induction heating is the level of control it offers. The knife maker can precisely control the degree of heat, ensuring it is concentrated only where it is needed, which reduces waste and improves the quality of the finished product.

Efficiency and Energy Savings

In comparison to traditional methods, induction heating is highly energy-efficient. The process directly heats the metal, reducing the amount of heat lost to the environment. This makes it a green, cost-effective solution for knife-making.

Safety and Environment-Friendly Aspects

Unlike flame-based methods, induction heating does not produce harmful gases, making it environmentally friendly. Moreover, it’s safe to use, as the risk of accidental burns is significantly reduced due to the lack of an open flame.

Induction Forge Vs Traditional Methods

Comparison with Other Heating Methods

Induction heating stands out when compared to other heating methods. Traditional techniques like coal forges often require significant energy, are less efficient, and pose safety risks. Induction forging, on the other hand, shines in these areas, making it a preferred choice among knife makers.

Why Knife Makers Choose Induction Forging

Knife makers choose induction forging for its precision, efficiency, and safety. It offers them the control they need to create high-quality knives, while also being more energy-efficient and safer to use than traditional methods.

Key Features to Consider in an Induction Heater for Knife Making

Power and Frequency

When choosing an induction heater for knife-making, you should consider its power and frequency. A higher power output and frequency mean faster heating times, which can be beneficial in a professional setting.

Control Features

An induction heater with adjustable controls for power and heat is crucial. This will allow you to fine-tune the heating process, achieving the ideal conditions for your knife-making needs.

Size and Portability

Size and portability matter, especially if your workspace is limited. A compact, portable induction heater can make your work easier and more efficient.

Safety Measures

Safety should be a top priority when choosing an induction heater. Look for models with built-in safety features, such as overheat protection and auto-shutoff mechanisms.

Step-by-Step Guide on Using Induction Heater for Knife Making

Setting Up the Induction Forge

When setting up the induction forge, ensure the unit is connected to a suitable power source. Place the induction coil in a stable position, ready to receive the metal bar.

Preparing the Knife for Forging

Before forging, the metal bar must be thoroughly cleaned. Any dirt or rust can interfere with the induction heating process.

Induction Forging Procedure

Place the metal bar within the coil and turn on the unit. Monitor the metal as it heats and begins to glow, then it’s ready for the forging process.

Post Forging Steps

After forging, the metal needs to cool down. Proper cooling is critical for achieving the desired hardness and durability in your finished knife.

Caring for Your Induction Forge: Maintenance Tips

Regular Maintenance Practices

Regular cleaning and inspection of your induction heater can prolong its life. Keep the coil free from dust and debris, and check the electrical connections regularly.

Troubleshooting Common Issues

Some common issues with induction heaters include insufficient heating and uneven heat distribution. These can often be resolved by adjusting the power settings or repositioning the metal within the coil.

Top Induction Forge Models for Knife Making

A Round-Up of Leading Models

Several induction forge models are suitable for knife-making, including those from brands like UltraHeat, Electroheat, and InductoForge. These brands are known for their reliability, performance, and value for money.

Factors to Consider When Buying

When buying an induction forge, consider factors such as power output, control features, size, portability, and safety features. Reviews and recommendations from fellow knife makers can also be valuable in making a decision.

Case Studies: Success Stories in Induction Knife Forging

How Induction Forging Revolutionized Knife Making

Induction forging has revolutionized knife-making in many ways. It has not only improved the quality and precision of knives but also made the process more efficient and safer.

Real-Life Examples of Successful Induction Knife Forging

Many professional knife makers have embraced induction forging and achieved great success. They credit this technology for its precision, control, and efficiency, all of which contribute to producing superior-quality knives.

Frequently Asked Questions

How Does Induction Heating Work?

Induction heating works by passing an alternating current through an induction coil, which generates a magnetic field. This field induces a flow of electrons in the metal piece, causing it to heat up.

What are the Advantages of Induction Heating in Knife Making?

Induction heating offers several advantages in knife making, including precision, efficiency, and safety. It allows for controlled and focused heating, uses energy more efficiently, and reduces the risk of accidental burns.

What Factors Should I Consider When Buying an Induction Heater for Knife Making?

When buying an induction heater for knife making, consider its power output and frequency, control features, size, portability, and safety features. It’s also helpful to check reviews and get recommendations from experienced knife makers.

Conclusion

Induction forging has undeniably made a substantial impact on the craft of knife-making. It has offered solutions to many challenges posed by traditional heating methods. With its ability to offer precise, efficient, and safer heating, it’s not surprising that this technology has gained widespread acceptance among knife makers.

The adoption of induction forging signifies a step forward in environmentally conscious practices in the knife-making industry. As we strive for greener, more sustainable methods, induction heating stands out as an energy-efficient solution that doesn’t compromise on performance or quality.