End mills and drill presses play vital roles in machining operations. While they serve different purposes, the concept of using a drill press as a mill piques interest among many. This exploration arises due to the distinctive qualities of an end mill, which crafts detailed workpieces, and the practicality of a drill press known for its versatility.

Such a notion arises from the functional similarities between the two tools. Both can cut into the material, make holes, and shape workpieces. However, using a drill press as a mill isn’t as straightforward as it may sound. It requires understanding both tools thoroughly and appreciating their differences and limitations.

Today, we will venture into this captivating aspect of machining. As someone who spends a good amount of time around these machines, I can shed light on the possibilities, challenges, and alternatives of this unusual adaptation.

End Mill: An Insight

Definition of End Mill

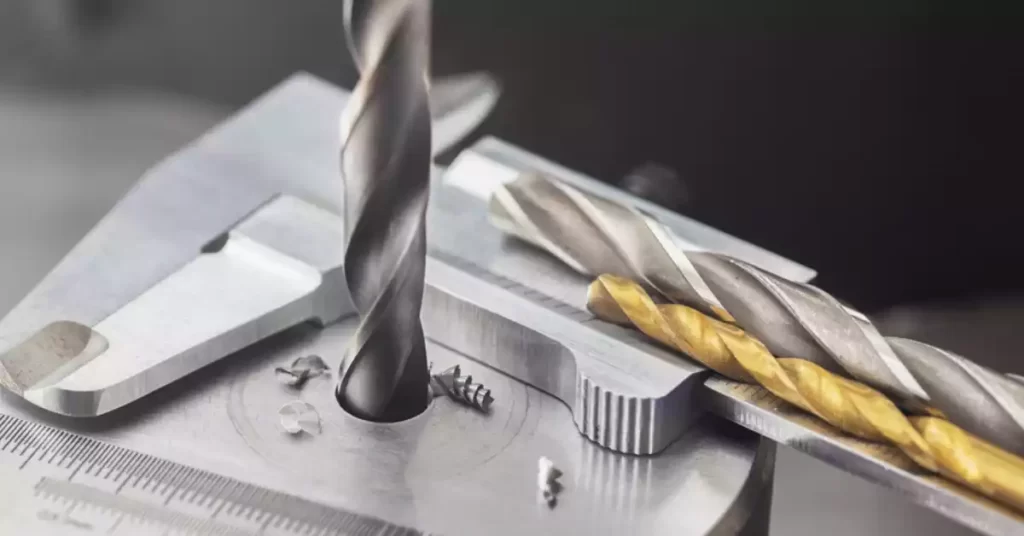

An end mill, primarily a cutting tool, is used in milling machines. With cutting edges on both ends and sides, it removes material from a workpiece to shape it as desired. Unlike a drill bit, it can cut in all directions, facilitating complex designs.

Types of End Mills

End mills come in several types, such as square end mills, ball end mills, and corner radius end mills. Each type caters to specific applications, be it detailed sculpting, grooving, or plunging.

Applications of End Mills

From automobile parts to intricate jewelry, end mills enable precision machining. They’re essential for cutting profiles, facing, creating slots, and even pocketing.

Drill Press: An Overview

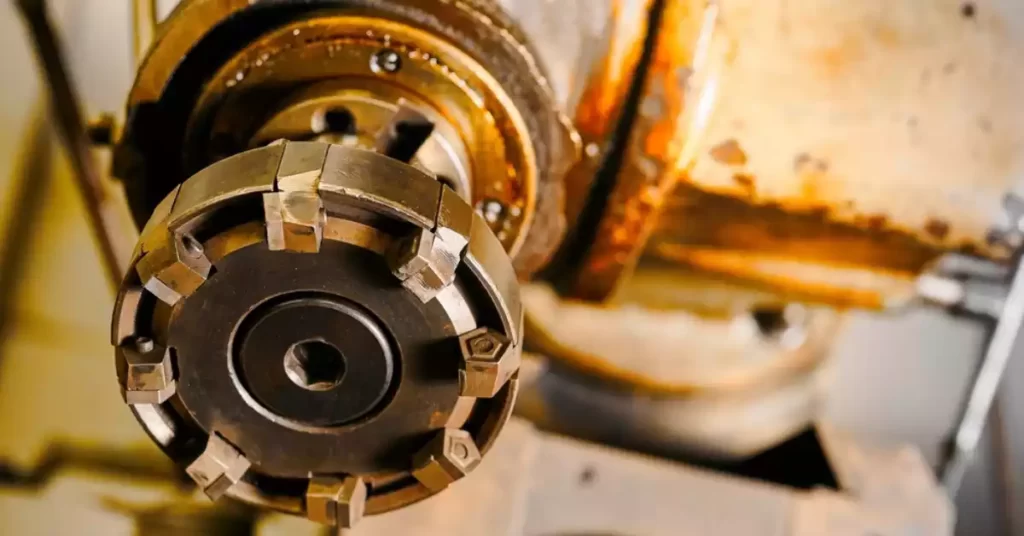

Understanding a Drill Press

A drill press, a stationary tool, excels in drilling holes with exact depths and sizes. It operates vertically, applying pressure to push the drill bit into the workpiece. The depth of the hole is easily adjustable, making it a go-to tool for precision drilling.

Types of Drill Presses

Benchtop and floor drill presses dominate the scene, offering variations in power and size. Other types like radial and magnetic drill presses cater to niche applications.

Use Cases for Drill Presses

A drill press is versatile. Beyond drilling, it can serve tasks like countersinking, counterboring, and even sanding with the right attachments.

Fundamental Differences: End Mill and Drill Press

Tool Design: End Mill vs Drill Press

While both tools deal with metals and wood, their design principles differ. End mills cut laterally and axially, whereas drill presses are predominantly axial. This stark difference implies a different construction and load-handling capacity for each tool.

Operation Techniques

Operating an end mill involves moving the tool and the workpiece in multiple directions. A drill press is a simpler tool, usually working in a vertical, downward motion.

Job Precision and Capability

End mills excel in tasks requiring precision and lateral cutting, like slot cutting and contouring. Drill presses, on the other hand, specialize in creating accurate, deep holes.

The Concept of Using a Drill Press as a Mill

Theoretically Possible, but Practically?

A drill press can cut into the material and create holes, like a mill. But, the lateral force that milling applies can cause significant wear and potential damage to a drill press, which isn’t designed to handle such stress.

Potential Risks and Dangers

Turning a drill press into a mill can be hazardous. The tool may not withstand lateral pressure, causing bits to break or the machine to fail. These events can lead to injuries.

Common Misconceptions

Some may assume that since both tools cut and shape material, they’re interchangeable. Unfortunately, that’s not the case. The core design and construction limit a drill press from fully assuming a milling machine’s role.

Considerations for Using Drill Press as Mill

Drill Press Limitations in Milling

A drill press lacks the rigidity to handle the stress from milling. Its spindle bearings aren’t designed for lateral loads, which milling necessitates.

Modifying Drill Press for Milling: Is it Worth it?

Modifying a drill press to perform as a mill is often more trouble than it’s worth. The risk of damaging the machine, reducing its lifespan, and compromising safety is high.

Safety Measures to Follow

If you still wish to use a drill press as a mill, you must strictly adhere to safety guidelines. These include using appropriate protective gear and not exerting lateral force beyond the machine’s capacity.

Expert Opinions: Drill Press as a Mill

Perspectives from Industry Professionals

Many professionals discourage the idea due to the structural differences and risk factors involved. The consensus leans towards investing in a milling machine if milling is required frequently.

Anecdotes from Machinists and Craftsmen

Some craftsmen recount successful minor milling tasks on a drill press, but these are exceptions rather than norms. The majority recommend using tools for their intended purposes.

Alternatives to Using Drill Press as a Mill

Mini Milling Machines

For hobbyists and small-scale work, mini milling machines are a great alternative. They offer milling functionality without requiring as much space or investment as a full-scale mill.

CNC Milling

CNC milling machines provide high precision and complex shaping capabilities. If your work requires intricate designs, these machines are worth considering.

Combination Mill-Drill Machines

Combination machines offer both drilling and milling functions. While they may not match a standalone machine’s performance, they serve as practical solutions for small workshops.

Frequently Asked Questions

Can you use a drill press as a mill?

In theory, yes. But practically, it’s not recommended due to the structural differences between the two machines and the potential risks involved.

Why can’t a drill press be used as a mill?

A drill press isn’t designed to handle the lateral pressure exerted during milling. Doing so can damage the machine and be unsafe.

What’s a viable alternative to using a drill press as a mill?

Options include mini milling machines, CNC milling, and combination mill-drill machines. The choice depends on your specific requirements and budget.

Conclusion

Machining tools, though similar in some aspects, have unique capabilities and limitations. The idea of using a drill press as an end mill emerges from a surface-level similarity. However, delving deeper, we see the risks and challenges this poses.

Drill presses and end mills are designed with specific roles in mind, each excelling in their own way. Any attempt to use them interchangeably could compromise their performance, lifespan, and most importantly, the operator’s safety.

Looking at the bigger picture, if milling is a recurring need, investing in a dedicated milling machine or an alternative like a mini mill or a CNC machine is a wise choice. It ensures you have the right tool for the job, leading to better results and safer operations.