In the heart of metallurgy, 1095/15n20 Damascus steel plays a significant role. This unique combination of metals results in a distinctive patterned blade that’s not only visually striking but also possesses superior strength and sharpness. The key to unlocking this blend’s potential is the heat treatment process, crucial for enhancing its properties.

Heat treatment is the controlled heating and cooling of the metal. When correctly applied to 1095/15n20 Damascus steel, it optimizes hardness, toughness, and edge retention, transforming the alloy into an effective cutting tool. Consequently, understanding this process becomes vital for anyone dealing with this form of steel.

Damascus steel heat treatment is an art form with science at its core. This process’s complexities lie in its multiple stages and the precision required to achieve the desired metallurgical transformation. Moreover, the results have significant impacts on the final product’s performance and aesthetics.

Basics of Heat Treatment

The heat treatment process fundamentally alters the steel’s internal structure. It involves heating the steel to a specific temperature, holding it at that temperature, and then cooling it down at a controlled rate. Through this process, the metal’s internal grains restructure, affecting its mechanical properties.

Specific Steps in 1095/15n20 Damascus Heat Treatment

Initial Heating: Austenitizing Phase

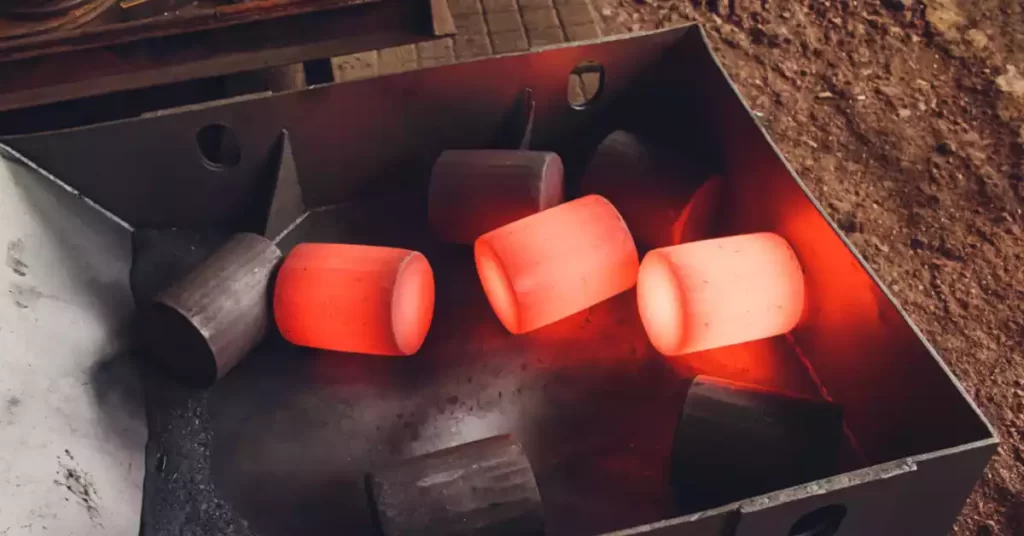

This initial phase, known as austenitizing, involves heating the steel to its critical temperature, typically around 1475°F for 1095/15n20 Damascus. During this stage, the steel’s internal structure changes into a phase known as austenite. This phase is significant as it allows carbon, a critical element in steel, to dissolve into the iron, forming a uniform solution.

Rapid Cooling: Quenching Phase

The next stage is quenching. This involves rapidly cooling the steel by immersing it into a cooling medium, most commonly oil. The abrupt temperature drop ‘freezes’ the austenite structure, trapping carbon within the steel’s structure and transforming it into a harder phase known as martensite. However, the creation of martensite leaves the steel very hard and brittle, unsuitable for practical use due to its lack of toughness.

Controlled Heating: Tempering Phase

The final stage in heat treating 1095/15n20 Damascus steel is tempering. This stage is aimed at reducing the brittleness induced by the quenching phase. The steel is heated again, but this time at a much lower temperature, typically between 400°F and 500°F.

This controlled heating allows some of the trapped carbon to diffuse out of the martensitic structure, creating a balance between hardness and toughness. The result is a more durable and usable piece of steel with good edge retention.

Factors Influencing the Heat Treatment Process

Composition of the Steel

The exact makeup of the steel plays a significant role in the heat treatment process. Different steels have different critical temperatures and require different heating and cooling rates to achieve the optimal balance of properties.

Heating and Cooling Rates

The rates at which the steel is heated and cooled also affect the outcomes of the heat treatment process. Rapid heating and cooling can lead to thermal stresses and potential deformation or cracking of the steel.

Treatment Temperature and Duration

The temperatures at which the austenitizing and tempering processes occur, as well as the duration of each phase, significantly influence the final properties of the steel. These parameters need to be carefully controlled to ensure the desired transformation takes place.

Benefits of Heat Treating 1095/15n20 Damascus

Improvement in Durability and Toughness

Heat treatment significantly enhances the steel’s durability and toughness. The tempering process, in particular, gives the steel an increased ability to resist deformation and breaking under stress. This is a critical characteristic for any tool expected to withstand hard use.

Enhancement in Edge Retention and Sharpness

A properly heat-treated blade will be able to maintain a sharp edge for a longer period. The austenitizing and quenching phases harden the steel, while the tempering process refines the grain structure, enhancing its ability to hold an edge.

Creation of Unique Patterns on Damascus Steel

One unique aspect of 1095/15n20 Damascus steel is the distinctive pattern that emerges during the heat treatment process. As the layers of different steel types interact under the intense heat and cooling, they form visible patterns on the surface. These patterns are a hallmark of Damascus steel, adding to its aesthetic appeal and making each piece unique.

Precautions and Tips

Safety Measures During Heat Treatment

As with any process involving high temperatures, safety is paramount. Always use heat-resistant gloves and safety glasses when handling hot steel. Work in a well-ventilated area to dissipate any potentially harmful fumes, and have a fire extinguisher on hand in case of emergencies.

Common Mistakes and How to Avoid Them

The heat treatment process requires precision and care. One common mistake is not heating the steel to its critical temperature during the austenitizing phase. This can be avoided by using a high-quality forge or kiln with accurate temperature controls.

Overheating the steel is another potential pitfall. This can lead to grain growth, resulting in a blade that is more prone to breakage. Stick to the recommended temperature ranges and use a thermometer to ensure accurate readings.

Another common error occurs during the quenching process. If the steel is not cooled rapidly enough, it may not fully transform into the hard martensite phase. Using the right quenching oil and ensuring the steel is evenly and quickly submerged can mitigate this.

Frequently Asked Questions

What is the Optimal Temperature for Heat Treating 1095/15n20 Damascus Steel?

The optimal temperature for the austenitizing phase of heat treating 1095/15n20 Damascus steel is approximately 1475°F. For the tempering phase, the temperature range is typically between 400°F and 500°F.

How Long Does the Heat Treatment Process Take?

The duration of the heat treatment process varies depending on the size and thickness of the steel, as well as the specific heating and cooling rates used. However, typically, the austenitizing phase can take around 10 to 20 minutes, while the tempering phase often involves two rounds of heating for approximately two hours each.

How Does Heat Treatment Affect the Patterns on Damascus Steel?

Heat treatment plays a crucial role in revealing the unique patterns on Damascus steel. The process brings out contrasts between the layers of different types of steel used in the Damascus blend, enhancing the visibility of the patterns.

Conclusion

The role of heat treatment in the creation of 1095/15n20 Damascus steel cannot be understated. This critical process is the bridge between raw materials and a high-performing, aesthetically pleasing final product.

Through controlled heating and cooling phases, heat treatment optimizes the metal’s hardness, toughness, and edge retention. It is the craftsmanship involved in this process that breathes life into the 1095/15n20 Damascus blend, resulting in a durable and functional blade.

The heat treatment process is a testament to the perfect marriage between art and science in metallurgy. While it necessitates precision and understanding of material properties, it also allows for the expression of the craftsman’s skill and creativity. When performed correctly, the result is an exceptional piece of 1095/15n20 Damascus steel that is as beautiful as it is functional.